In 2016, Rohloff introduced a new version of their renowned SPEEDHUB 500/14 14-speed internal gear hub that works with through axle frames. Dubbed the SPEEDHUB A12, Rohloff offers versions to fit frames with 12x142, 12x148, 12x177, and 12x197mm spacing. The SPEEDHUB A12 is nearly identical to the standard Rohloff SPEEDHUB 500/14, with the exception of how the hub connects to the frame.

A12 hubs mount to the frame with frame-specific adapters and custom bolts, so Rohloff requires that frames be verified for compatibility before they make the hub available for purchase. As a result, A12 hubs are always special order items, and delivery takes anywhere from a few weeks to a couple months.

This tech talk covers the details of the A12 system and provides instructions to guide you through the ordering process.

A12 hubs are NOT through-axle hubs!

With through axle frames, the defining interface dimensions for a rear hub are usually based around 2 measurements—the distance between the dropouts and the outer diameter of the axle. The combination of these two measurements provides a standard used by hub makers to ensure that hubs are easily interchangeable between different frames with the same dropout spacing. Most through axles on the market today feature a 12mm outer diameter, so hubs must include a 12mm hole through the center in order to accept the axles.

When riders first encounter Rohloff A12 hubs, most assume the hub is a true through axle version of the SPEEDHUB with a 12mm hole through the center. In reality, A12 hubs do not include a 12mm hole through the center but instead use a pair of 7mm bolts to secure the hub to the frame. These bolts are combined with a pair of adapters that reduce the openings in the frame dropouts from 12mm to 7mm.

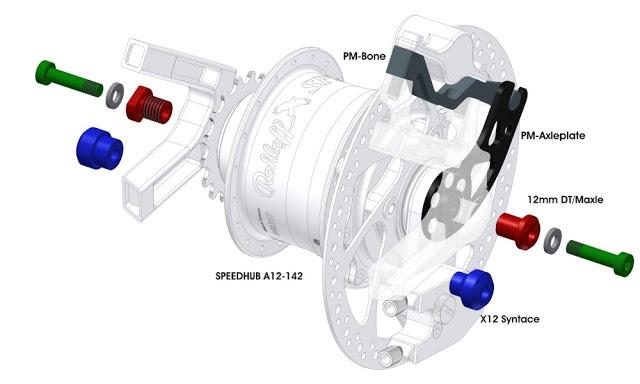

The pieces of the A12 system are shown in the image below. The red and blue pieces are inserts that reduce the openings in the dropouts from 12mm diameter to 7mm, and they will be sized specifically for compatibility with your dropouts and type of through axle. The green pieces are custom M7 bolts that hold the wheel into the frame, and the grey pieces are locking washers that keep the bolts from loosening. The ends of the hub are threaded to receive the M7 bolts, but the rest of the internals are identical to the original, quick-release or threaded axle SPEEDHUBs.

A12 versions use the same proven 14-speed gearbox that has transported riders to and from work, round-the-world tours, trail rides, and other self-powered (and increasingly motor-assisted) adventures for the past 20 years.

Why hasn’t Rohloff created a true through-axle version of the SPEEDHUB?

When Rohloff designed the SPEEDHUB in the mid-1990s, 5mm quick-release skewers were standard across the bike industry. The SPEEDHUB was designed around this standard and does not have space for a 12mm shaft to pass through the center.

It should be noted that at the time, it was revolutionary for an internal gear hub to have a quick release axle, and the SPEEDHUB remains the only internal gear hub on the market to offer this option (all others use a threaded axle with axle nuts). In order to fit a larger 12mm axle, the entire hub would need to be redesigned, which to-date Rohloff has been unwilling to entertain for a variety of reasons. Most importantly, creating space for a 12mm axle would likely lead to a larger and heavier hub because everything would need to scale in size around the axle increase, which is counter to the desire of most riders for a smaller, lighter hub.

A12 hubs mount to the frame with frame-specific adapters and custom bolts, so Rohloff requires that frames be verified for compatibility before they make the hub available for purchase. As a result, A12 hubs are always special order items, and delivery takes anywhere from a few weeks to a couple months.

This tech talk covers the details of the A12 system and provides instructions to guide you through the ordering process.

A12 hubs are NOT through-axle hubs!

With through axle frames, the defining interface dimensions for a rear hub are usually based around 2 measurements—the distance between the dropouts and the outer diameter of the axle. The combination of these two measurements provides a standard used by hub makers to ensure that hubs are easily interchangeable between different frames with the same dropout spacing. Most through axles on the market today feature a 12mm outer diameter, so hubs must include a 12mm hole through the center in order to accept the axles.

When riders first encounter Rohloff A12 hubs, most assume the hub is a true through axle version of the SPEEDHUB with a 12mm hole through the center. In reality, A12 hubs do not include a 12mm hole through the center but instead use a pair of 7mm bolts to secure the hub to the frame. These bolts are combined with a pair of adapters that reduce the openings in the frame dropouts from 12mm to 7mm.

The pieces of the A12 system are shown in the image below. The red and blue pieces are inserts that reduce the openings in the dropouts from 12mm diameter to 7mm, and they will be sized specifically for compatibility with your dropouts and type of through axle. The green pieces are custom M7 bolts that hold the wheel into the frame, and the grey pieces are locking washers that keep the bolts from loosening. The ends of the hub are threaded to receive the M7 bolts, but the rest of the internals are identical to the original, quick-release or threaded axle SPEEDHUBs.

A12 versions use the same proven 14-speed gearbox that has transported riders to and from work, round-the-world tours, trail rides, and other self-powered (and increasingly motor-assisted) adventures for the past 20 years.

Why hasn’t Rohloff created a true through-axle version of the SPEEDHUB?

When Rohloff designed the SPEEDHUB in the mid-1990s, 5mm quick-release skewers were standard across the bike industry. The SPEEDHUB was designed around this standard and does not have space for a 12mm shaft to pass through the center.

It should be noted that at the time, it was revolutionary for an internal gear hub to have a quick release axle, and the SPEEDHUB remains the only internal gear hub on the market to offer this option (all others use a threaded axle with axle nuts). In order to fit a larger 12mm axle, the entire hub would need to be redesigned, which to-date Rohloff has been unwilling to entertain for a variety of reasons. Most importantly, creating space for a 12mm axle would likely lead to a larger and heavier hub because everything would need to scale in size around the axle increase, which is counter to the desire of most riders for a smaller, lighter hub.

A12 ordering process

Ordering an A12 hub is not a simple matter of placing the order and having it arrive a few days later.

First, dropout thicknesses need to be determined to ensure the parts will work together. Insertion depth of the mounting bolts is critical to proper functioning of the A12 system and must be standardized across all frames. Because dropouts vary in shape, thickness, axle capture method, and thread pitch between manufacturers—or even between models from the same manufacturer—Rohloff produces a variety of adapters to fit most frames.

Rohloff has devised a testing method to determine both whether a given frame’s dropouts are compatible with the A12 mounting bolts and which specific frame adapters will be required. Rohloff’s testing procedure measures thickness in two distinct ways and then compares the results to provide a double check. Cycle Monkey can complete this process in-house if dropouts or frames are sent to us, or send the Rohloff testing kit to dealers.

Once the dropouts have been measured, the results are submitted to Rohloff for review and approval, along with the frame's serial number. Upon approval, the hub can be added to our next bulk shipment, which occurs approximately every 2 months. We are also happy to ship hubs separately with an additional international shipping fee.

Note that each hub will be registered to an individual frame, and the warranty will be tied to exclusive use with that frame. Additional paperwork can be submitted for use with an additional frame(s).

Does your frame have Paragon sliding dropouts? Check out Paragon Inserts for A12 Hubs

Ready to get started?

Despite the somewhat complicated ordering process, Cycle Monkey has helped multitudes of riders with through axle frames successfully enjoy the wide-ranging benefits of Rohloff’s SPEEDHUB.

If you’d like to get started with the ordering process or have additional questions about the A12 system, please don’t hesitate to drop us a line or place an order.

- The driveline of the 12x142mm hubs is the same as the standard 135mm hubs.

- The driveline of the 12x148mm hubs is 3mm narrower than the 12x142mm or standard hubs and the wheel is dished 3mm towards the drive side. The entire 6mm of additional width between 142mm and 148mm hub spacing is located on the drive side of the hub to accommodate the SPEEDHUB shifting mechanism. This biases the hub 3mm the left of the bike’s centerline. As a result, the flange offset values are 33mm left side and 27mm right side.

- The driveline of all SPEEDHUB XL and XXL fat bike hubs is the same, so 10x170mm QR, 12x177mm A12, 10x190mm QR, and 12x197mm A12 have the same sprocket position. 190/197mm hubs have 10mm of extra axle length on either end compared to 170/177mm hubs.

Ordering an A12 hub is not a simple matter of placing the order and having it arrive a few days later.

First, dropout thicknesses need to be determined to ensure the parts will work together. Insertion depth of the mounting bolts is critical to proper functioning of the A12 system and must be standardized across all frames. Because dropouts vary in shape, thickness, axle capture method, and thread pitch between manufacturers—or even between models from the same manufacturer—Rohloff produces a variety of adapters to fit most frames.

Rohloff has devised a testing method to determine both whether a given frame’s dropouts are compatible with the A12 mounting bolts and which specific frame adapters will be required. Rohloff’s testing procedure measures thickness in two distinct ways and then compares the results to provide a double check. Cycle Monkey can complete this process in-house if dropouts or frames are sent to us, or send the Rohloff testing kit to dealers.

Once the dropouts have been measured, the results are submitted to Rohloff for review and approval, along with the frame's serial number. Upon approval, the hub can be added to our next bulk shipment, which occurs approximately every 2 months. We are also happy to ship hubs separately with an additional international shipping fee.

Note that each hub will be registered to an individual frame, and the warranty will be tied to exclusive use with that frame. Additional paperwork can be submitted for use with an additional frame(s).

Does your frame have Paragon sliding dropouts? Check out Paragon Inserts for A12 Hubs

For riders whose frames feature sliding dropouts that are compatible with Paragon’s inserts, Cycle Monkey has developed a solution that eliminates the need for the red and blue adapters shown above and allows you to slide the hub directly into the dropouts and secure it with just the A12 fixing bolts. These inserts have IS brake tabs for use in combination with our Monkey Bone and an OEM2 axle plate. Check them out over at Paragon (part #s DR4055, B4055, DR4056, B4056).

Ready to get started?

Despite the somewhat complicated ordering process, Cycle Monkey has helped multitudes of riders with through axle frames successfully enjoy the wide-ranging benefits of Rohloff’s SPEEDHUB.

If you’d like to get started with the ordering process or have additional questions about the A12 system, please don’t hesitate to drop us a line or place an order.

Additional notes on A12 Hub drivelines and wheels:

- The driveline of the 12x142mm hubs is the same as the standard 135mm hubs.

- The driveline of the 12x148mm hubs is 3mm narrower than the 12x142mm or standard hubs and the wheel is dished 3mm towards the drive side. The entire 6mm of additional width between 142mm and 148mm hub spacing is located on the drive side of the hub to accommodate the SPEEDHUB shifting mechanism. This biases the hub 3mm the left of the bike’s centerline. As a result, the flange offset values are 33mm left side and 27mm right side.

- The driveline of all SPEEDHUB XL and XXL fat bike hubs is the same, so 10x170mm QR, 12x177mm A12, 10x190mm QR, and 12x197mm A12 have the same sprocket position. 190/197mm hubs have 10mm of extra axle length on either end compared to 170/177mm hubs.